|

|

Once a small amount of damage happens and lets the weather in, the

damage soon gets much worse. |

|

Eventually, the kilns collapse and become overgrown. As time passes, the evidence of the lime making industry will be completely lost.

|

|

By

repairing some of the surviving structures

now we can ensure that this fascinating

and important part of our industrial heritage

will survive for future generations to

enjoy. |

|

With

some repairs now, the larger kilns will

survive for many years to come. |

|

Other kilns are beyond repair and are better off left alone. |

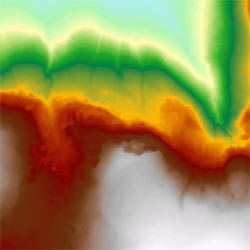

A digital terrain model of Herbert’s

Quarry

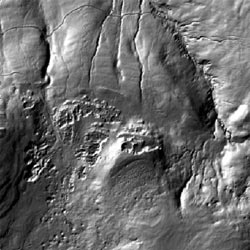

Shaded relief image of the same area

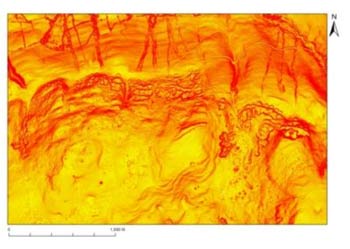

A 'slope model' image of the quarries

|

Quarry

Survey

In order to decide which kilns it is important

to preserve, and to decide what repairs

were needed, we needed to do a thorough

survey of the whole site. Herbert’s Quarry has been surveyed

from the air with a technique using lasers

called LiDAR (Light Detection and Ranging).

This results in a very detailed contour

map made up of 8,757,573 LiDAR points!

By itself the LiDAR survey can be difficult

to understand, but using computers the

LiDAR data can be viewed in different ways

to make it more understandable. |

|

We

can also drape an aerial photograph of

the area over the LiDAR survey to produce

a 3D image of the site.

We can use this bird’s

eye view to help us understand the whole

of the site as it is today.

By comparing the

site as it is today with old maps and

photographs of the same area we can work

out how the site has changed over the years,

and which parts are the oldest.

By combining

all this information together we have

been able to create a computer based digital

plan of Herbet's Quarry. This can be

used to demonstrate how the quarries, and

kilns the have developed through time,

and how the road system in the surrounding

landscape has also changed.

The next step was to check

how things really looked by doing a 'ground

survey'... |

|

Field survey

Dyfed Archaeological Trust worked with volunteers to make a detailed record of the remains of the lime industry at Herbert's Quarry. First we used aerial photographs and LiDAR survey to make a plan of the area, plotting the locations of Quarries, kilns, buildings, spoil heaps, roads and tracks. |

|

Next we braved the elements and spent several days exploring the quarries, photographing all the kilns, filling in record forms, drawing plans and taking measurements. |

|

We also recorded different types of bricks and any other clues we could find. This brick was made in Bonnybridge in Scotland ! |

|

Each kiln is associated with a specific area of quarry and has its own set of spoil heaps and tracks. This suggests that each kiln and quarry may have been leased out separately by the landowners (the Cawdor Estate). |

|

The detailed survey has shown us that there were kilns and quarries at various levels up the hill side, similar to the other quarries to the west. Later quarrying and spoil tips higher up the slopes have either destroyed or buried many of the earlier workings. In this photo, a kiln is almost completely buried underneath a spoil heap. There are the remains of at least 36 kilns at the site. |

|

Around the edges of the quarry, a few traces of the early workings still survive. This photograph shows where soil has been dug away to reveal the limestone outcrop. Immediately to the left is the modern quarry face . |